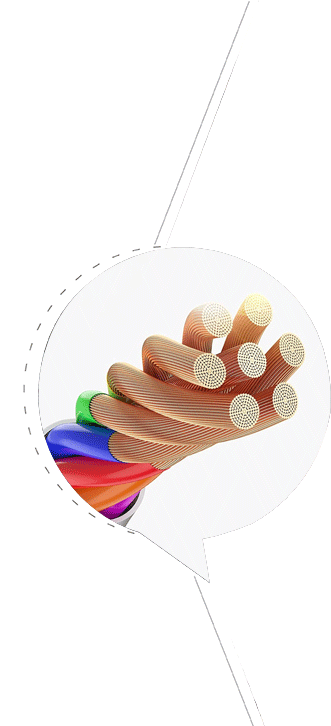

1. Product Features and Benefits

Tin-plated copper clad copper wire has the following notable features:

Excellent conductivity: The tin coating improves the conductivity of the copper wire, making it perform well in electrical equipment.

Anti-oxidation and anti-corrosion: The tin coating can effectively prevent oxidation and corrosion of the copper wire in a humid, high temperature or corrosive environment, extending its service life.

Good weldability: The tin coating increases the welding performance of the copper wire, making it easier to connect and repair.

Lightweight and flexible: The tin-plated copper clad copper wire is lightweight and easy to bend and process.

2. Precautions for safe use

Avoid damage: During storage or transportation, avoid physical damage to the tin-plated copper clad copper wire, such as scratches or breaks, as this may damage the tin coating and cause the copper wire to be exposed to air and accelerate oxidation.

Proper labeling and management: Ensure that there are clear labels on the product packaging to identify the product ID and quality information to avoid confusion.

Preventing misuse: Tinned copper wire is similar in appearance to bare copper wire, but may be mistaken for aluminum wire in some cases. Therefore, the color and structure of the wire surface should be carefully checked before use to ensure correct identification.

3. Installation and maintenance

Connection and terminal processing: Tinned copper wire is often used for electrical connection and terminal processing. It is recommended to use flux-free tinned copper compression terminals (such as ring crimping) for connection to ensure good electrical contact.

Shielding and protection: Tinned copper wire is often used for the shielding layer or outer sheath of the cable to improve electromagnetic compatibility (EMC) and anti-interference ability. During installation, attention should be paid to the correct connection and fixation of the shielding layer.

Environmental adaptability: Tinned copper wire is suitable for harsh environments such as outdoor installation, underground cables and marine applications, but it is necessary to ensure that it complies with relevant standards and specifications during installation.

4. Maintenance and troubleshooting

Regular inspection: Regularly check the surface condition of the tinned copper wire to ensure that the tinning layer is not worn or peeled off. If the tinning layer is found to be damaged, the wire should be replaced in time.

Cleaning and maintenance: When cleaning tinned copper wire, avoid using strong acid or strong alkaline chemicals to avoid damaging the tinned layer. It is recommended to wipe with a mild detergent.

Troubleshooting: If the tinned copper wire has electrical performance degradation or corrosion problems, it may be caused by environmental factors or improper installation. At this time, check whether the line connection is firm and reapply the tinned layer to restore its performance.

5. Special application scenarios

High-voltage cable: In high-voltage cables, tinned copper wire is often used for conductor cores or shielding layers to improve temperature resistance and corrosion resistance.

Robot cable: In robot cables, tinned copper wire is used as a conductor core or shielding layer to meet high flexibility and anti-interference requirements.

Aerospace: In the aerospace field, tinned copper wire is widely used in wire construction due to its low cost, high conductivity and corrosion resistance.

EN

EN  English

English Español

Español عربى

عربى