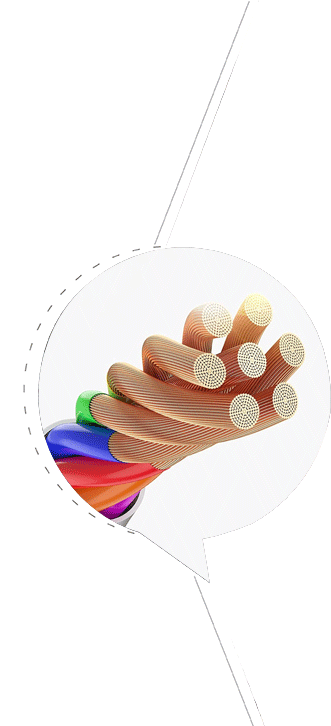

Application and performance advantages of Al-Mg alloy wire in aerospace conductors

Al-Mg alloy wire has become a key material for aerospace conductor systems due to its light weight, high strength, corrosion resistance and excellent electrical conductivity. This paper systematically analyzes the composition ratio, microstructural characteristics and performance of Al-Mg alloy in extreme environments, and compares it with traditional copper conductors to explain its comprehensive advantages in weight reduction, fatigue resistance and cost-effectiveness.

Material properties and composition design

Composition optimization: Typical composition is Mg (2-6%), trace Mn, Cr (to increase recrystallization temperature), and the balance is Al. Mg solid solution strengthening improves strength (tensile strength can reach 300-400 MPa) while maintaining conductivity ≥55% IACS.

Microstructure: Fibrous structure is formed after cold deformation, and the grain size can be adjusted by annealing to balance strength and ductility.

Performance advantages

Lightweight: The density (2.7 g/cm³) is only 30% of that of copper conductors, which significantly reduces the mass of aircraft cable systems.

Excellent specific strength: The strength/density ratio is more than 2 times that of copper wire, suitable for high mechanical stress areas (such as wiring of wing moving parts).

Corrosion resistance: The synergistic effect of the surface Al₂O₃ film and Mg resists salt spray and hot and humid environments, and the service life is more than 50% higher than that of copper wire.

Fatigue resistance: The crack growth rate under cyclic load is low, suitable for spacecraft environments with frequent vibrations.

Conductive performance regulation

By controlling the Mg content (≤3%) and the impurity Fe/Si content, the conductivity can be optimized to 58-60% IACS, meeting the MIL-W-5086L aviation wire standard.

Tin plating or silver coating can further improve the high-frequency signal transmission performance.

Application scenarios

Aircraft main circuit system: For example, the Boeing 787 uses Al-Mg alloy wire to replace 30% of copper wire, reducing the weight of a single machine by about 100kg.

Spacecraft wiring: NASA uses it in satellite wiring harnesses, taking advantage of its anti-cosmic ray-induced aging properties.

High temperature area wires: Improved alloys with added Sc/Zr can work for a long time at 150°C (such as engine compartment wiring).

EN

EN  English

English Español

Español عربى

عربى