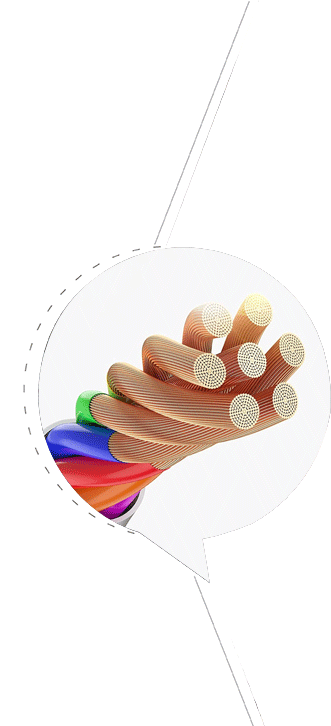

Performance characteristics of CCS stranded wire:

Electroplated CCS single and stranded wires are new composite materials made by uniformly electroplating 99.9% electrolytic copper molecules onto high-quality low-carbon steel cores. This product has both the strength and toughness of steel, as well as the good conductivity and corrosion resistance of copper. The product is widely used in high-frequency coaxial cables, steel network communication, electrified railways, subway and light rail, grounding wires for power and petrochemical systems, etc. Compared with copper stranded wire, it has the advantages of low density, high strength, and low cost, and is an updated product of traditional pure copper stranded wire.

CCS Stranded wire

+86 18015848610

|

Cross-sectional area(mm2) |

Single root * Number of roots(mm) |

Approximate outer diameter(mm) |

Conductivity(%) |

Copper layer thickness(mm) |

Unit weight(kg/km) |

Conductivity(%) |

Copper layer thickness(mm) |

Unit weight(kg/km) |

Conductivity(%) |

Copper layer thickness(mm) |

Unit weight(kg/km) |

Conductivity(%) |

Copper layer thicknes(mm) |

Unit weight(kg/km) |

|

16 |

1.7*7 |

5.1 |

20 |

0.02 |

130 |

25 |

0.045 |

132 |

30 |

0.074 |

134 |

40 |

0.13 |

140 |

|

25 |

2.14*7 |

6.5 |

20 |

0.025 |

203 |

25 |

0.058 |

205 |

30 |

0.093 |

207 |

40 |

0.165 |

210 |

|

35 |

2.57*7 |

7.6 |

20 |

0.03 |

280 |

25 |

0.069 |

283 |

30 |

0.109 |

285 |

40 |

0.195 |

288 |

|

50 |

1.8*19 |

9 |

20 |

0.021 |

390 |

25 |

0.049 |

393 |

30 |

0.078 |

395 |

40 |

0.139 |

395 |

|

3.0*7 |

0.036 |

0.082 |

0.13 |

0.232 |

||||||||||

|

70 |

2.14*19 |

11 |

20 |

0.025 |

545 |

25 |

0.058 |

548 |

30 |

0.093 |

550 |

40 |

0.165 |

554 |

|

3.5*7 |

0.042 |

0.096 |

0.152 |

0.27 |

||||||||||

|

95 |

2.52*19 |

12.6 |

20 |

0.03 |

758 |

25 |

0.069 |

760 |

30 |

0.109 |

762 |

40 |

0.195 |

775 |

|

120 |

2.84*19 |

14 |

20 |

0.034 |

953 |

25 |

0.078 |

955 |

30 |

0.125 |

958 |

40 |

0.219 |

960 |

|

150 |

2.28*37 |

16 |

20 |

0.027 |

1200 |

25 |

0.062 |

1203 |

30 |

0.099 |

1205 |

40 |

0.176 |

1208 |

|

3.15*19 |

0.038 |

0.087 |

0.137 |

0.243 |

||||||||||

|

185 |

2.52*37 |

17.6 |

20 |

0.03 |

1503 |

25 |

0.069 |

1505 |

30 |

0.109 |

1507 |

40 |

0.195 |

1510 |

|

3.52*19 |

0.042 |

0.096 |

0.152 |

0.27 |

||||||||||

|

240 |

2.88*37 |

20 |

20 |

0.034 |

1970 |

25 |

0.079 |

1975 |

30 |

0.127 |

1980 |

40 |

0.22 |

1990 |

|

4.0*19 |

0.048 |

0.11 |

0.174 |

0.309 |

||||||||||

|

300 |

3.2*37 |

22.4 |

20 |

0.038 |

2405 |

25 |

0.088 |

2430 |

30 |

0.139 |

2465 |

40 |

0.247 |

2480 |

Application areas:

The product is widely used in grounding wires for lightning protection, electrified railways, subway and light rail, power and petrochemical systems, etc.

Product description:

CCS (Copper Clad Steel) stranded wire is a composite wire with a steel core covered with a copper layer, combining the high strength of steel and the excellent conductivity of copper. It is widely used in scenarios that require a balance between strength and conductivity:

Features of CCS stranded wire:

High strength and high toughness:

The steel core provides excellent mechanical strength and excellent tensile properties, and can be used in situations where it is subjected to greater mechanical stress.

Excellent conductivity:

The copper layer provides good conductivity while reducing the cost of all-copper wires.

Lightweight design:

Compared to all-copper wires, CCS stranded wires are lighter and easier to transport and install.

Corrosion resistance:

The surface copper material has strong corrosion resistance and is suitable for harsh environments.

High cost-effectiveness:

Combining the advantages of performance and economy, it is an economical alternative to all-copper wires.

Application scope and field:

Communication industry:

Widely used in communication cables and signal transmission lines.

Suitable for the center conductor of antennas and coaxial cables, used in wireless communications and cable TV systems.

Power and transmission and distribution systems:

Used as ground wires, lightning conductors, and conductors on high-voltage transmission towers.

Applicable to power lines that require high-strength conductors.

Railways and transportation:

Used as grounding protection wires and track signal systems for railways.

CCS stranded wires are also commonly used in signal and transmission systems in transportation facilities.

Building and structural engineering:

Suitable as lightning protection strips, grounding conductors and shielding wires for buildings.

Cable networks used in large buildings to meet the requirements of strength and conductivity.

Aerospace and aerospace fields:

Used as light wires, used in special environments that require high strength and corrosion resistance.

New energy fields:

Used in grounding systems in wind and solar energy fields.

Electrical connection components used in new energy power generation equipment.

Notes on the selection of CCS stranded wires:

Copper layer thickness: Select an appropriate copper layer ratio (such as 10%, 30%, etc.) according to the conductivity requirements.

Wire diameter and strength: Determine the wire diameter and tensile strength according to the actual application environment.

Environmental conditions: Special environments (such as high corrosion or high mechanical load) require the selection of specially designed CCS stranded wires.

Changzhou Yuzisenhan Electronic Co., Ltd.

Changzhou Yuzisenhan Electronic Co., Ltd. offer CCS Stranded wire. We are CCS Stranded wire Manufacturers and CCS Stranded wire Suppliers. Our company has a number of production lines: domestic copper-clad steel, copper-clad steel inlaid in line, and copper-clad aluminum manufacturing has the strength of one of the manufacturers.

Our company has advanced copper-clad steel, copper-clad aluminum, copper-clad steel inlay line production equipment, and professional testing instruments, in the selection of raw materials, the use of excellent raw materials; At the same time, a complete quality assurance system has been established to ensure that the company's products are subject to strict quality control from raw materials to finished products. Our company has passed the 1s09000:2000 quality management system certification.

Ask Our Experts For Free.

Please Give Us Your Questions And Suggestions. We Will Respond To Your Message In A Timely Manner.

Hot Products

News

-

industry news 2025-04-24

Copper Clad Aluminium Wire (CCA Wire) has become a popular choice for antenna systems due to its unique combination of lightweight prop...

View More -

industry news 2025-04-17

Copper clad steel wire (CCS wire) is a versatile and cost-effective solution for grounding systems in electrical and telecommunications...

View More -

industry news 2025-04-10

Copper coated steel wire (CCS wire) is a versatile and cost-effective material used in telecommunications, electrical grounding, and fe...

View More -

industry news 2025-04-03

Copper Clad Steel Wire: A Composite Material with Excellent PerformanceCopper Clad Steel Wire is a composite material that combines cop...

View More -

industry news 2025-03-27

1. The role of CCS WireCCS Wire is a key material used in battery connection systems to achieve electrical connections between cells an...

View More -

industry news 2025-03-20

According to the latest search results, the specific applications of CCA wire (Copper Clad Aluminum Wire) in the construction industry ...

View More

CCS Stranded wire Industry Knowledge

CCS twisted wire in high-frequency signal transmission: key technologies for electromagnetic shielding and impedance control

1. Core requirements for high-frequency signal transmission on wires

Skin effect: high-frequency current is concentrated on the surface of the conductor, and the conductive advantage of the copper layer in copper-clad steel (CCS).

Impedance matching: avoid signal reflection, the influence of twisted wire structure on characteristic impedance (such as 50Ω/75Ω).

Electromagnetic interference (EMI) shielding: the need to suppress external noise in high-frequency environments.

2. Design optimization of CCS twisted wire

Material selection:

The relationship between copper layer thickness and high-frequency conductivity (such as 0.05mm vs. 0.1mm copper-clad steel).

Tensile strength and flexibility balance of steel core.

Twisted structure:

The relationship between the number of layers, twist length and signal loss (such as 7-strand vs. 19-strand twist).

The influence of tight twisting vs. loose twisting on capacitance and inductance.

3. Key technologies of electromagnetic shielding

Shielding layer matching: Combination of CCS twisted wire and aluminum foil/braided shielding (such as SFTP structure).

Grounding design: The effect of the grounding method of the copper layer on the suppression of common-mode noise.

High-frequency test data: Comparison of the insertion loss (Insertion Loss) and return loss (Return Loss) of CCS and pure copper wires.

4. Impedance control method

Geometric parameter regulation: The influence of conductor diameter and dielectric constant of insulation layer (such as PE vs. PTFE) on impedance.

Production process: The effect of twisting uniformity on impedance stability (such as the accuracy requirements of high-speed twisting machines).

Simulation and actual measurement: Simulation by HFSS or ADS software, combined with TDR (time domain reflectometer) verification.

5. Application scenarios and cases

5G communication cable: CCS twisted wire lightweight solution in base station antenna feeder.

High-speed data cable: Alternative design to reduce cost in USB 3.0/HDMI cables.

Military and aerospace: Reliability performance of high-frequency wiring harnesses in extreme environments.

EN

EN  English

English Español

Español عربى

عربى