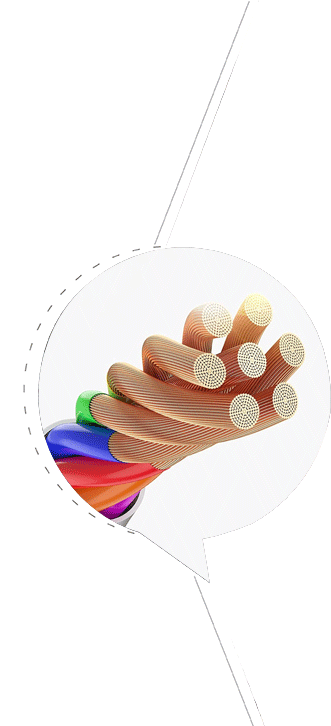

What are the specific effects of the copper layer thickness of T-CCS Wire on its performance?

The copper layer thickness of T-CCS Wire has the following specific effects on its performance:

Conductivity: Copper has good conductivity. The increase of copper layer thickness can make the conductivity of the wire closer to pure copper. More copper can provide more free electrons, which is convenient for current transmission, thereby effectively reducing resistance loss. For example, in the internal wiring of some electronic equipment with high transmission efficiency requirements, appropriately increasing the thickness of the copper layer can reduce the attenuation of signal transmission and ensure signal quality.

Corrosion resistance: Copper has a certain corrosion resistance, and a thicker copper layer can provide better protection for the internal steel core. It can block the contact between the steel core and external corrosive substances, slow down the rusting speed of the steel core, and extend the service life of the wire. For example, in some communication cables used in outdoor environments, T-CCS Wire with a thicker copper layer can better resist the erosion of humid air, acid rain, etc.

Flexibility: Generally speaking, the thicker the copper layer, the higher the flexibility of the wire. Because copper has good ductility and is relatively soft, increasing the thickness of the copper layer can improve the softness of the overall wire to a certain extent, making it easier to process and use. In the laying process of wires and cables, wires with good flexibility are easier to bend and lay, and can adapt to different laying environments and path requirements.

Solderability: The thickness of the copper layer also affects the solderability of T-CCS Wire. A thicker copper layer can provide more metal to combine with solder during welding, which is conducive to forming a good welding joint and improving the firmness and reliability of welding. In the welding of electronic components, good solderability can ensure the stability of the connection and reduce the occurrence of problems such as cold soldering and desoldering.

How to choose the T-CCS Wire specification suitable for a specific application scenario?

To select the T-CCS Wire specification suitable for a specific application scenario, the following aspects need to be considered:

Application environment

Temperature: In high temperature environments, such as next to industrial furnaces, high temperature resistant T-CCS Wire specifications should be selected. Consider increasing the thickness of the copper layer to improve heat dissipation performance, and at the same time select suitable insulation materials to prevent high temperature from causing insulation performance degradation. In low temperature environments, such as outdoors in cold areas, the low temperature toughness of the wire should be considered, and the specification of a slightly thicker copper layer can be appropriately selected to avoid the wire becoming brittle and breaking due to low temperature.

Humidity and Corrosion: In a humid or corrosive gas environment, such as coastal areas or chemical workshops, attention should be paid to the corrosion resistance of the wire. T-CCS Wire with a thicker copper layer and good tinning layer quality should be selected to provide better protection and prevent the wire from being corroded.

Electrical Performance Requirements

Conductivity: For occasions where large currents need to be transmitted, such as power transmission lines, the required wire cross-sectional area should be calculated according to the current size, and T-CCS Wire specifications that can meet the current carrying requirements should be selected. At the same time, in order to reduce resistance loss, the thickness of the copper layer can be appropriately increased to improve the conductivity. In high-frequency signal transmission applications, such as radio frequency communication lines, T-CCS Wire with a smaller diameter and a relatively thick copper layer should be selected to reduce the signal loss caused by the skin effect and ensure the transmission quality of the signal.

Resistance: Select the appropriate specification according to the specific circuit requirements for resistance. If lower resistance is required, T-CCS Wire with thick copper layer and thick wire diameter can be selected; if the resistance requirement is not particularly strict, relatively economical specifications can be selected on the premise of meeting other performance requirements.

Mechanical performance requirements

Tensile strength: In applications such as overhead wires and cable traction that need to withstand large tensile forces, T-CCS Wire specifications with high steel core strength and thick wire diameter should be selected to ensure that the wire can withstand the corresponding tensile force without breaking. For example, in overhead transmission lines with large spans, the required tensile strength needs to be calculated based on the line span and the external force to be applied, and the appropriate specifications should be selected.

Flexibility: For occasions that require frequent bending or movement, such as connecting wires inside electronic equipment and cables of mobile robots, T-CCS Wire with good flexibility should be selected. This usually means specifications with moderate copper layer thickness, small wire diameter and more flexible structure to facilitate bending and adapt to different motion states.

Cost factors

Generally speaking, the thicker the copper layer, the larger the wire diameter and the higher the quality of T-CCS Wire, the higher the cost. When selecting specifications, it is necessary to comprehensively consider cost factors while meeting the performance requirements of the application scenario. If the performance requirements are not extremely strict, some indicators can be appropriately lowered and specifications with higher cost performance can be selected to control costs. For example, in some general electrical connections that do not require particularly high conductivity, T-CCS Wire with a slightly thinner copper layer thickness and a moderate wire diameter can be selected to meet basic electrical performance requirements and save costs.

Installation Space

When the installation space is limited, such as inside a small electronic device, it is necessary to select a T-CCS Wire specification with a smaller diameter to fit the small space. However, it should be noted that reducing the wire diameter may affect its current carrying capacity and mechanical strength, and a trade-off needs to be made on the basis of meeting the electrical and mechanical performance requirements. If the installation space is relatively ample, such as in a large distribution cabinet, a T-CCS Wire specification with a larger wire diameter and better performance can be selected.

EN

EN  English

English Español

Español عربى

عربى