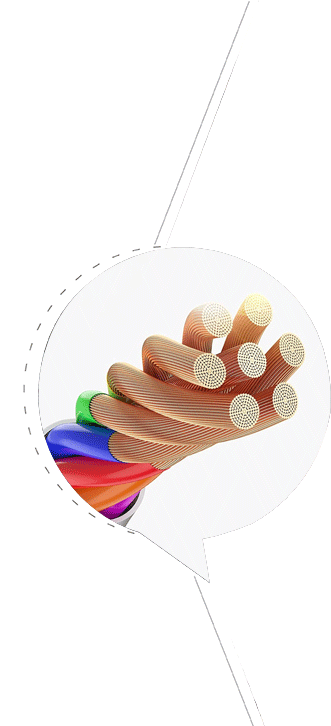

How does the ratio of the copper layer thickness to the steel core diameter of CCS Wire affect its performance?

The ratio of the copper layer thickness to the steel core diameter of CCS Wire has an important impact on its performance, as follows:

Conductive properties

Copper has much better conductivity than steel. The increase in the thickness of the copper layer can provide more low-resistance channels for the current, which can effectively reduce the DC resistance of the wire and improve the conductivity. For example, in situations where a large current needs to be transmitted, appropriately increasing the thickness of the copper layer can reduce the power loss and heat generation on the line. However, if the copper layer is too thick, it will increase the cost and the effect of improving the conductivity will gradually weaken.

The steel core mainly plays a supporting role and contributes less to the conductivity. However, the change in the diameter of the steel core will affect the overall resistance distribution of the wire. When the diameter of the steel core is relatively large, the current will be more concentrated on the surface of the copper layer. In the case of high frequency, this skin effect is more obvious, which may cause the high-frequency resistance to increase and affect the signal transmission quality.

Mechanical properties

The steel core has high strength and toughness, and is the main part of the CCS Wire that withstands tension and external forces. The larger the diameter of the steel core, the better the tensile strength, compressive strength and bending resistance of the wire, and the better it can adapt to various complex use environments, such as the overhead transmission line bearing its own weight and external forces such as wind.

The copper layer can also improve the flexibility of the wire to a certain extent, but its effect on the mechanical properties is smaller than that of the steel core. However, the appropriate thickness of the copper layer can improve the smoothness of the wire surface, reduce the damage caused by factors such as friction during use, and indirectly improve the mechanical reliability of the wire. If the copper layer is too thin, it is easy to break or fall off when subjected to external forces, affecting the overall performance of the wire.

Corrosion resistance

Copper has good corrosion resistance, and the copper layer can provide effective protection for the steel core to prevent the steel core from contacting with corrosive media such as air and moisture outside. The thicker the copper layer, the better the protection effect, which can extend the service life of the wire. Especially in some harsh environments, such as humid coastal areas or industrial environments with chemical corrosion, a thicker copper layer can significantly improve the corrosion resistance of CCS Wire.

When the ratio of copper layer thickness to steel core diameter is appropriate, the copper layer can evenly cover the surface of the steel core to form a complete protective film. If the ratio is inappropriate, such as the copper layer is too thin or uneven, the steel core is easily exposed to the external environment and corrosion occurs, thereby reducing the mechanical strength and conductivity of the wire.

What is the difference between the application of CCS Wire in power transmission and communication fields?

There are the following differences in the application of CCS Wire (copper clad steel wire) in power transmission and communication fields:

Performance requirements

Power transmission: more emphasis on current carrying capacity and mechanical strength. Power transmission requires large-capacity electric energy to be transmitted from the power generation end to the power consumption end, so CCS Wire is required to be able to withstand large currents and have low resistance to reduce power loss. At the same time, in applications such as overhead transmission lines, the wires are also required to have sufficient mechanical strength to withstand external forces such as their own weight, wind, and ice to ensure the safe and stable operation of the line.

Communication field: high requirements for high-frequency transmission performance and signal integrity. Communication signals are usually high-frequency signals, requiring CCS Wire to maintain low signal attenuation, distortion and delay during transmission to ensure communication quality, such as high-speed data transmission, clear voice and image communication, etc. In addition, it is also required to have good anti-interference performance to avoid the influence of external electromagnetic interference on communication signals.

Specification selection

Power transmission: According to factors such as transmission power and distance, CCS Wire with a larger wire diameter is usually selected to meet the current carrying requirements. For example, in high-voltage transmission lines, CCS Wire with a thicker diameter may be used, and the ratio of its copper layer thickness to the steel core diameter will also be optimized according to the specific electrical and mechanical performance requirements, generally focusing more on ensuring sufficient conductivity and mechanical strength.

Communication field: CCS Wire with a relatively small wire diameter, relatively thin copper layer thickness but good uniformity is usually selected. This is because the signal current in the communication line is relatively small, and the current carrying capacity is not required, but better high-frequency transmission characteristics are required. Smaller wire diameters are also convenient for layout and installation in communication equipment and lines, while reducing costs.

Application scenarios

Power transmission: Mainly used in overhead transmission lines of power systems, busbar connections of substations, and other scenarios. In some areas that are more cost-sensitive and have high requirements for mechanical strength, such as remote mountainous areas or rural power grids, CCS Wire can be used as a substitute for copper wires to reduce construction costs while ensuring power transmission.

Communication field: Commonly used in feeders of communication base stations, indoor and outdoor communication cables, etc. For example, in mobile communication networks, feeders used to connect base station antennas and radio frequency equipment usually use CCS Wire to achieve efficient transmission of high-frequency signals. In addition, CCS Wire is also used in the internal wiring of some data centers to connect servers and network equipment to meet the needs of high-speed data communication.

Installation and maintenance

Power transmission: Special power construction equipment, such as wireline vehicles, are required during installation to complete the erection of overhead lines or the laying of cables. In terms of maintenance, it is necessary to regularly check the mechanical damage, corrosion, and contact resistance of the connection points of the lines to ensure safe and reliable power transmission. Since power transmission lines usually have high voltages, maintenance work needs to strictly comply with power safety operating procedures.

Communications: During installation, more attention is paid to the cable laying method and the reliability of the connection to avoid signal interference or attenuation. For example, in indoor communications wiring, attention should be paid to the cable bending radius and shielding measures to prevent signal leakage and external interference. In terms of maintenance, communication signals are mainly monitored and tested through professional testing equipment to promptly discover and solve signal quality problems, such as checking whether the cable connection is loose or whether there is excessive signal attenuation.

EN

EN  English

English Español

Español عربى

عربى