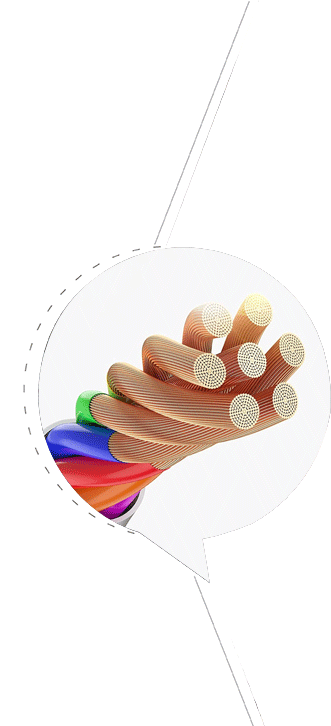

The key role of T-CCA wire in modern industry: from manufacturing to maintenance

T-CCA (copper clad aluminum) wire plays an important role in modern industry, and its unique properties make it widely used in many fields. The following are the key roles of T-CCA wire from manufacturing to maintenance:

1. Key role in manufacturing

Cost-effectiveness: T-CCA wire combines the conductivity of copper and the lightweight characteristics of aluminum, with a lower cost than pure copper wire, suitable for large-scale production.

Lightweight design: The aluminum core makes T-CCA wire light in weight, easy to transport and install, especially suitable for industries that need to reduce weight, such as automotive and aerospace.

Conductive properties: The copper outer layer provides good conductivity, suitable for power transmission and electronic equipment.

Mechanical properties: T-CCA wire has high tensile strength and flexibility, suitable for complex wiring environments.

2. Application areas

Power transmission: used for medium and low voltage power transmission, low cost and good conductivity.

Communication industry: used to manufacture communication cables, such as network cables and telephone cables, with excellent signal transmission performance.

Automotive industry: used in automotive wiring harnesses, reducing weight and maintaining conductivity.

Home appliances: widely used in internal wiring, balancing cost and performance.

3. Key role in maintenance

Corrosion resistance: The copper outer layer provides good corrosion resistance, prolongs service life and reduces maintenance needs.

Easy to install and maintain: Lightweight and flexibility make it easy to install and maintain, reducing labor costs.

Reliability: It can still maintain stable performance in harsh environments and reduce failure rates.

Environmental protection: The use of aluminum reduces dependence on copper resources and meets environmental protection requirements.

4. Future development trends

Technological innovation: With technological progress, the performance of T-CCA wire will be further improved.

Application expansion: The application in emerging fields such as new energy and smart grids will increase.

Standardization and normalization: The improvement of industry standards will promote its wider application.

EN

EN  English

English Español

Español عربى

عربى